WASTE GO solves your problems within the Treatment Plant!

Are any of these problems familiar?

- Exceeding design capacity

- Odor control costs skyrocketing

- Insufficient retention time in secondary aeration basins

- Foaming digesters

- Scum layers in anaerobic digesters

- Grease plugs in lines

- Hydraulic overloading

- Seed source needed after digester cleaning

- Grease balls in digesters

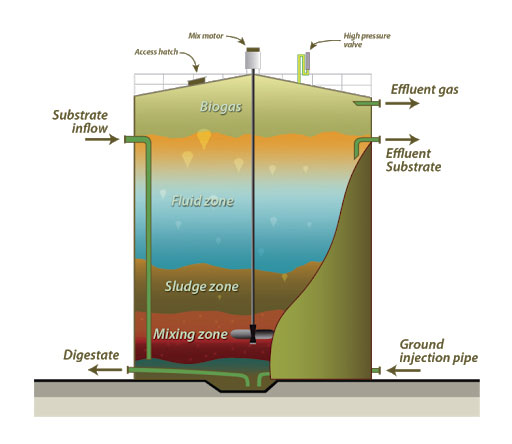

In Anaerobic & Aerobic digesters, Waste Go applied directly to the U-Tubes will:

- Eliminates scum blanket, foam and digests grease

- Increases volatile solids reduction

- Improves gas production

- Improves settling characteristics

- Improves mixing

- Controls odors by directly attacking the cause

- Prevents grease buildup in sludge transfer lines

- Stabilizes pH, volatile acids and alkalinity. Digester operating parameters respond by becoming linear and less likely to vary

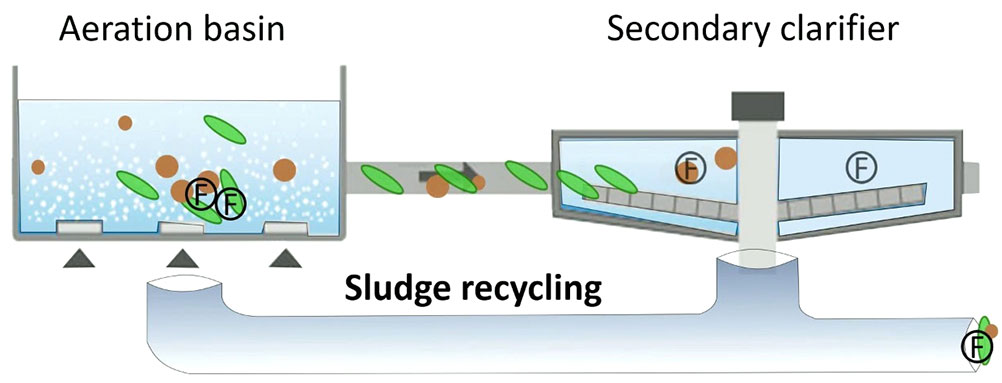

In Aeration Basins and Clarifiers:

- Provides faster recovery after hydraulic overload (washout)

- Helps overcome toxic stress conditions and regain normal activity

- Provides the most efficient microbes and catalysts to speed up volatile solids digestion

- Eliminates grease build up on freeboard surfaces and grating

The advantages of WASTE GO are clear!

- 100% SAFE to all living organisms – NSF Certified

- Decreases solids removal by reducing 80%+ solids

- Prevents cleanouts and hauling from digesters that have become “dead”

- Almost eliminates FOG’s (fats, oils and grease)

- Produce a better quality sludge

- Economical – A fraction of the cost of mechanical

- Saves on odor control costs

- Saves on labor

- Saves costs on chlorine and eliminates the need for grease solvents and hydrogen peroxide

- Seed your digester and eliminate sludge transport